These heavy duty Vertical Axis machines are the workhorse of the centrifugal casting industry in producing a variety of ferrous and non-ferrous castings in a variety of shapes and sizes. Animation showing what happens during the vertical centrifugal casting processTo learn more about the centrifugal casting process visit us at httpswwwm.

Vertical Centrifugal Casting Machine Download Scientific Diagram

They are provided with the systems of a programmed controlled crystallization to obtain alloys with the required properties.

. Our engineers complete 3D designs of every customers centrifugal casting machine before any metal is cut. Centrifugal casting machines for ferrous and non-ferrous castings. High g-forces applied to the molten metal in the.

1000 liners soil drain pipes up to 280 pcsh of DN1003000 acc. Rs 20 Lakh Set Get Latest Price. A detailed study of the centrifugal pouring process and the inherent fluid dynamics was performed to develop a conceptual design and operation parameters and inputoutput system variables were established.

The centrifugal force induced by the rotation pushes the molten metal against the inner wall of the mold to create the intended shape. Vertical Centrifugal Casting Machine Manufacturer Gibson Centri Tech Ltd. Vertical Centrifugal Casting Machines Further Information.

2 Vertical centrifugal casting This type of casting is followed for cylinder type bodies having ring geometry. To DIN EN 877 TAILOR-MADE Solutions for. Initial rotor head design a showed the hole for mould fitting and b showed the hole to be fitted with the motor shaft.

Our machine designs produce castings in both ferrous and non-ferrous material from a few pounds. The temperature of the mold is set at 400C. This paper shows the special design performed to develop a vertical axis centrifugal casting machine for that purpose.

The vertical centrifugal casting machines adopt fully automated systems utilizing. With 45 years of experience in the Machine Design Manufacture Equipment Installation and Personnel training for Vertical and Horizontal centrifugal casting machines. The compact design of the centrifugal machine makes it ideal for small operating areas.

We manufacture Horizontal Centrifugal Casting Machines Machine is designed primarily to accommodate and spin permanent steel moulds for large tube shaped castings. After the second mixing stage the vertical centrifugal casting machine is prepared to work. Capable of handling up to 100000 lbs 45359 kgs of dynamic loads with casting sizes up to 120 3M Diameter.

Vertical centrifugal casting machines can be used to cast both ferrous and non-ferrous materials and come equipped standard with water cooled shafts and variable speed drives. In this method the mould is rotated in a vertically axis. The molding dies can be oriented horizontally horizontal centrifugal casting or vertically vertical centrifugal casting.

A detailed study of the centrifugal pouring process and. 34 For Medals Artifacts and Awards. This video shows what happens during the centrifugal casting process.

What is vertical centrifugal casting. The vertical centrifugal casting machines adopt fully automated systems utilizing programmable logic controllers PLC with functions of automatic pouring automatic mold coating automatic mold inner wall cleaning and automatic extraction. The work has been completed with design and fabricated of a low cost horizontal and vertical centrifugal casting machine with the main accessories for producing a.

For this purpose a special design of a vertical axis centrifugal casting machine was developed. Tulsa Centrifugal Casting Machines LLC founded by the leading centrifugal casting specialists in the USA. Isometric view of the to be used in centrifugal casting technique 18 42.

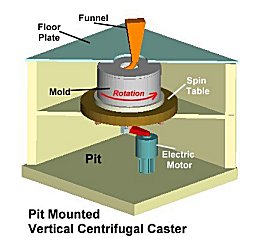

Designed for pit mounting with variable speed. The machines have the elastic-damping. All process steps are conducted simultaneously.

Vertical Centrifugal Casting Machine. The molds are revolved clockwise inside the machine to each process step. Horizontal centrifugal casting machine 12 23.

Horizontal Centrifugal Casting Machine. Cylinder liners up to 90 pipesh comes up to appr. Vertical centrifugal casting machines.

A typical vertical centrifugal casting machine is shown. Areas using centrifugal casting. Vertical centrifugal casting machines installed below the ground level for maximum operator safety are used for producing bushings and castings that are relatively large in diameter and short in length.

Please visit the following links for more information or email our sales team salesgibsoncentritechcouk. The motivation for this project comes from the necessity of the casting research group of the Department of Mechanical Engineering to obtain Functionalized Graded Materials and. Centrifugal casting consists of a number of processes in which the centrifugal force set up by the rotation of a part of the casting is utilized to shape the casting fill the mould and help solidify and strengthen the metal Pavlovic et al 2009.

For this purpose a special design of a vertical axis centrifugal casting machine was developed. Vertical centrifugal casting machine 12 41. Tulsa Centrifugal Casting Machines LLC founded by the leading centrifugal casting specialists in the USA.

Our machine designs produce. This article discusses the mold design for different types of sand molds and permanent molds and their production considerations. The vertical centrifugal casting machine is prepared before the starting with the melting process the required rotation speed is determined through the change of inverter and pulse input unit Tachometer.

There is a difference between vertical centrifugal casting and horizontal centrifugal casting. The casted products diameter ranged from 50mm to 2000mm with length ranged from 50mm to 2000mm. When using a centrifugal casting machine the cost of thermal drying is reduced.

When to Rely on Centrifugal Casting. Casting machines with a vertical axis are employed for manufacturing of relatively short ring castings of any complexity. It is capable of centrifugally casting cast iron alloy irons nickel chromium alloys.

The design team utilises an efficient design process with our engineers using the best tools available for 2D and 3D modelling design. Centrifugal casting machine is needed in the mineral processing industry to reduce waste and increase mineral separation efficiency. Our floor and pit mounted vertical centrifugal casting machines are used to produce the duplexed mill rolls cylinder liners bronze or copper alloy tubes brake drums discs bottle molds flywheels and stainless grates etc.

Fully automated hot mold centrifugal casting machine. Vertical machines are often chosen to produce castings that are. With 40 years of experience in the Machine Design Manufacture Equipment Installation and Personnel training for Vertical and Horizontal centrifugal casting machines.

Horizontal centrifugal casting preferred for the tube geometry. Horizontal centrifugal casting machine is shown in Fig.

Constructive Scheme Of A Centrifugal Casting Machine With A Vertical Download Scientific Diagram

Pro E 3d Model Of Centrifugal Casting Machine Download Scientific Diagram

Tulsa Centrifugal Casting Machines Vertical Machines

Vertical Centrifugal Casting Machine For Casting Rolls Federal Pipe Centrifugal Casting Machine Co Ltd

Tulsa Centrifugal Casting Machines Vertical Machines

Vertical Centrifugal Casting Machine

Pdf Design And Development Of A Centrifugal Casting Machine For Pistons Production Semantic Scholar

0 comments

Post a Comment